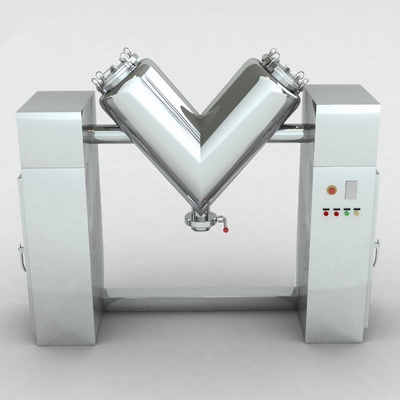

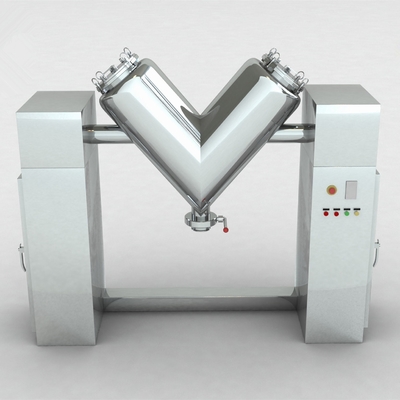

VH Series Pharmaceutical Dry Powder Granule Agitator V Type Mixing Machine

V Type Powder Mixer

Introduction

V-type mixer is driven by the drive shaft which rotates around the center of the rotary axis, during which material starts gravity diffusion movement along with the V-shaped inclined cylinder, when the connection of the V-shaped cylinder is rotated in the upper position, the materials collected at the bottom are diverted into the two inclined cylinder bodies, so that the material of each inclined cylinder body can also enter the other inclined body through the joint ports tube inside. With the continuous rotation of the cylinder, the continuous changes of the cylinder body, V-cylinder material is repeatedly dislocation, translation, diffusion, so as to achieve uniform mixing.The structure of mixing barrel is unique. The mixing barrel is unique. The barrel is made of stainless steel and its internal walls are polished. The outside appearance is beautiful. The mixing is uniform, with wide application, meets GMP standard.

Main structure features

This machine adopts labor feeding and enclosed flapper valve for discharging. It will not produce powder dust, and it also will not produce mechanical compression and strong friction during mixing. So the material particles can remain intact. The mixing barrel is made of stainless steel, which won’t pollute the material. Besides, this machine has timing device, which can control the mixing time of materials.

Main Application

The machine is fully sealed and dust- free operation be in line with the dust- free processing requirements.

The mixer is used for mixing the dry material grains inmedical, chemical, food, metallurgical and other industries.

| TYPE |

FULL VOL.

(m³) |

LOADING

RATIO |

L

(mm) |

W

(mm) |

H

(mm) |

DISCHARGE DIAMETER

(mm) |

ROTATING HEIGHT

(mm) |

ROTATING SPEED

(rpm) |

ELECTRIC POWER

(kW) |

WEIGHT

(kg) |

| WKS-V-0.1 |

0.1 |

0.4~0.8 |

1650 |

500 |

1550 |

φ80 |

1600 |

12 |

0.75~1.1 |

180 |

| WKS-V-0.3 |

0.3 |

0.4~0.8 |

1900 |

600 |

1750 |

φ100 |

1900 |

12 |

1.1~1.5 |

350 |

| WKS-V-0.5 |

0.5 |

0.4~0.8 |

2300 |

700 |

2100 |

φ150 |

2250 |

9 |

1.5~2.2 |

550 |

| WKS-V-1 |

1 |

0.4~0.8 |

2700 |

1000 |

2500 |

φ150 |

2700 |

9 |

2.2~4 |

1000 |

| WKS-V-1.5 |

1.5 |

0.4~0.8 |

3000 |

1000 |

2600 |

φ200 |

2900 |

8 |

4~5.5 |

1100 |

| WKS-V-2 |

2 |

0.4~0.8 |

3200 |

1200 |

3100 |

φ200 |

3250 |

8 |

4~7.5 |

1500 |

| WKS-V-2.5 |

2.5 |

0.4~0.8 |

3950 |

1500 |

3550 |

φ200 |

3800 |

7 |

5.5~11 |

1700 |

| WKS-V-3 |

3 |

0.4~0.8 |

4100 |

1500 |

3600 |

φ200 |

3850 |

6 |

7.5~11 |

1800 |

Pictures

Working Principles

The reducing mechanism drives the barrel rotary, and the length of two barrels is different, which will produce asymmetry. And then the machine take advantage of this asymmetry for mixing materials. When the machine is running, materials from the decomposition to the combination, as potential energy differences, which will produce lateral force to promote the horizontal exchange of materials; and materials from the combination to the decomposition, as materials plane differences, which will produce lateral force to promote the horizontal exchange of materials again. The barrels rotary one cycle, which will make 25% of materials flow from one barrel to the other one; at the same time the materials will also produce radial flow, and then the materials can horizontally and radially decompose, alternating combination, so that the materials can mix evenly.

FAQ

1. Can your machine meet our need well?

We will supply you a proposal as to your specific requirement, and each machine is customized to satisfy customer's need well.

2. Are you a factory or a trading company?

We are the manufacturer.

3. What's your payment way?

T/T by our bank account directly, or by Alibaba's trade assurance service, or by the West Union, or in cash.

4. How can you ensure the machine's quality after we put the order?

Before the delivery, we will send you machine's pictures and videos, or you can come to us to have the quality checking by

yourself, or by the third party inspection organization contacted by your side.

5. We are afraid you won't deliver us the machine after we pay you the money.

Please note our above business license and certificates. And if you don't trust us, you can use Alibaba's trade assurance service or by LC.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!